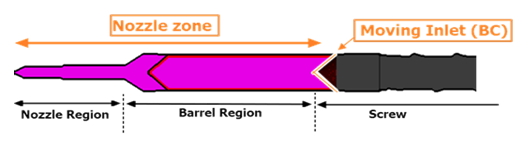

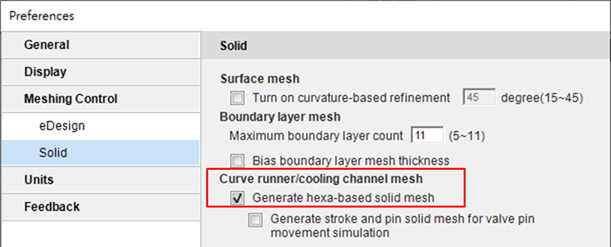

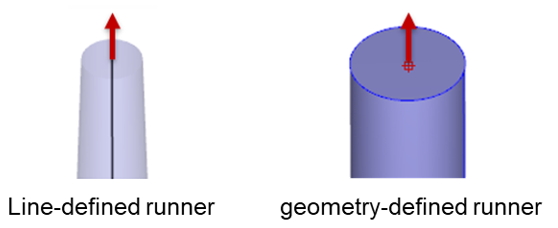

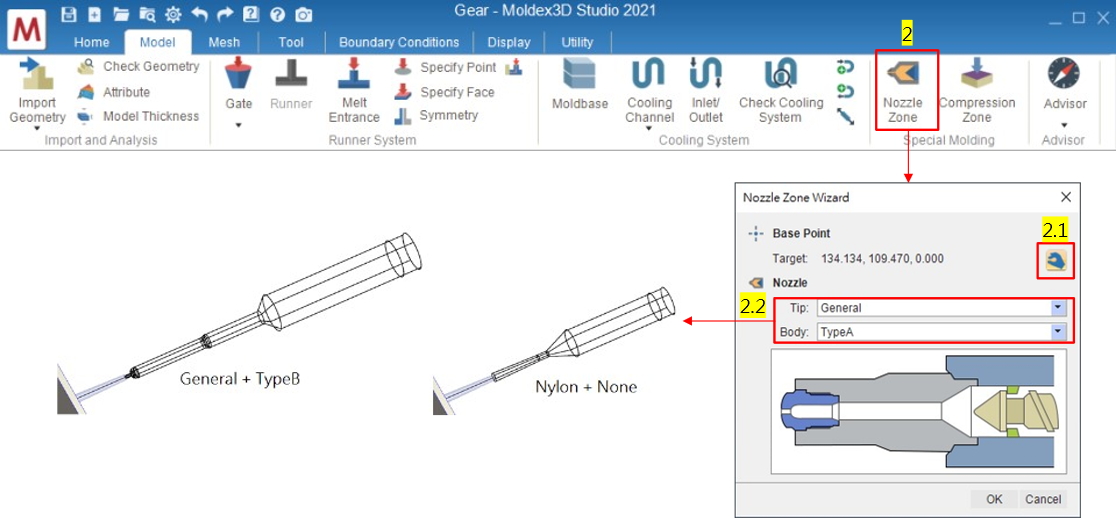

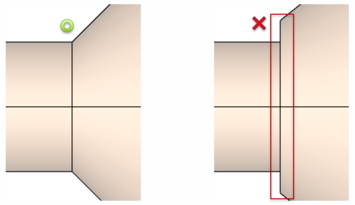

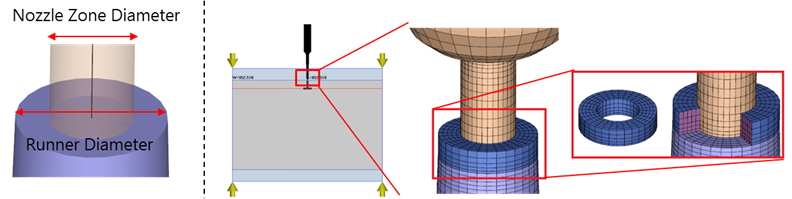

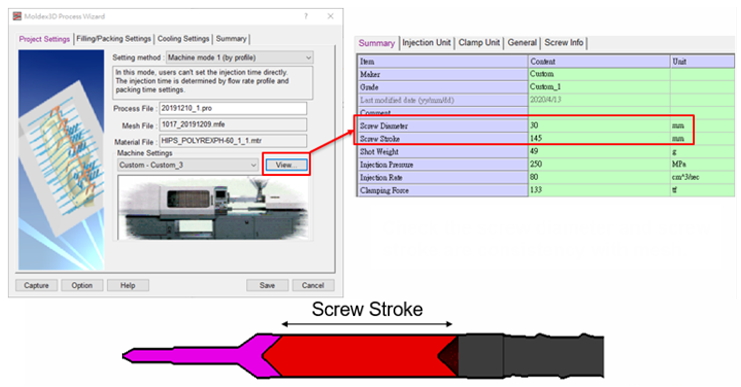

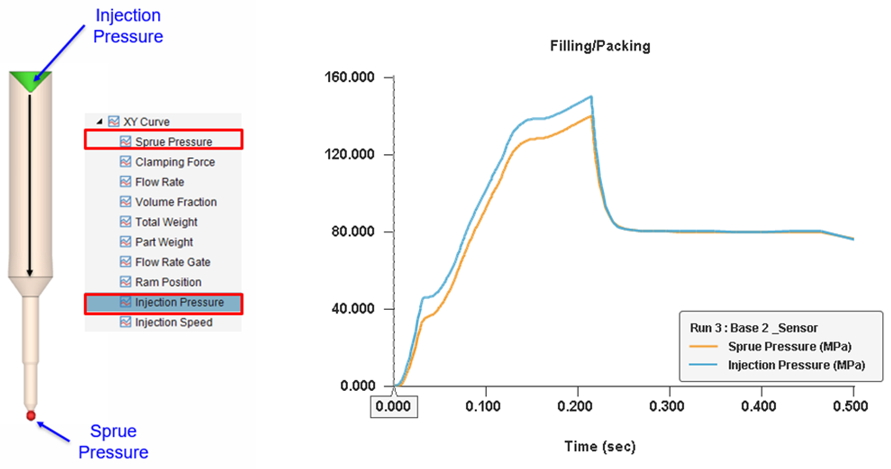

In the molding analysis, the simulation inside the barrel will affect the melt conditions when it enters the cavity, and further impact the whole injection molding process simulation. To better describe the melt behaviors such as compression inside the barrel, it is necessary to have good model construction of the injection units. The injection units, including nozzles and screws, can have complicated and diverse designs, so how to achieve both high-quality modeling and development efficiency is a critical issue. To eliminate the gap between simulation and on-site conditions and improve the accuracy injection pressure prediction, Moldex3D has included the dynamic simulation at the filling and packing stages inside the barrel. Moreover, Moldex3D 2021 further provides the Nozzle Zone Wizard feature for users to easily create a true nozzle type, making analysis more accurate and reducing the loading in pre-processing. Limitation Step 1:Model Preparation Note: (1)   If users want to edit the nozzle zone type after the setting, remove the nozzle zone model and reset with the wizard again. If users just want to modify the nozzle zone dimension, make sure it is continuous at the junctions of each segment. The cross-sectional dimensions of the runner should be larger than the Nozzle Zone. (2)   When a nozzle zone is connected to the runner, the default moldbase is attached to the junction of the nozzle zone and the runner. A nozzle type’s ring-shaped solid mesh will then be automatically generated (the models with mold base and mold plates components are both supported). Step 2:Analysis Settings Step 3: result interpretation Automatic Door Air Shower,Stainless Steel Automatic Door Tunnel Air Shower,Automatic Silding Door Air Shower,Stainless Steel Sliding Door Air Shower Wuxi Zijing Purification Engineering Co., Ltd , https://www.zijingjh.com

Ben Lai, Engineer at Technical Support Team, Moldex3D

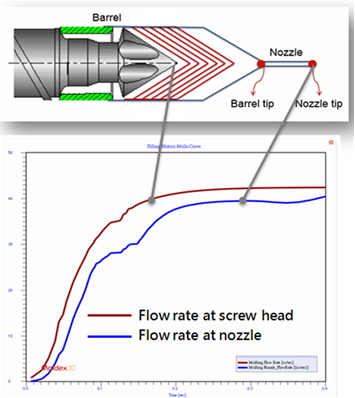

Flow rate changes caused by the screw compression

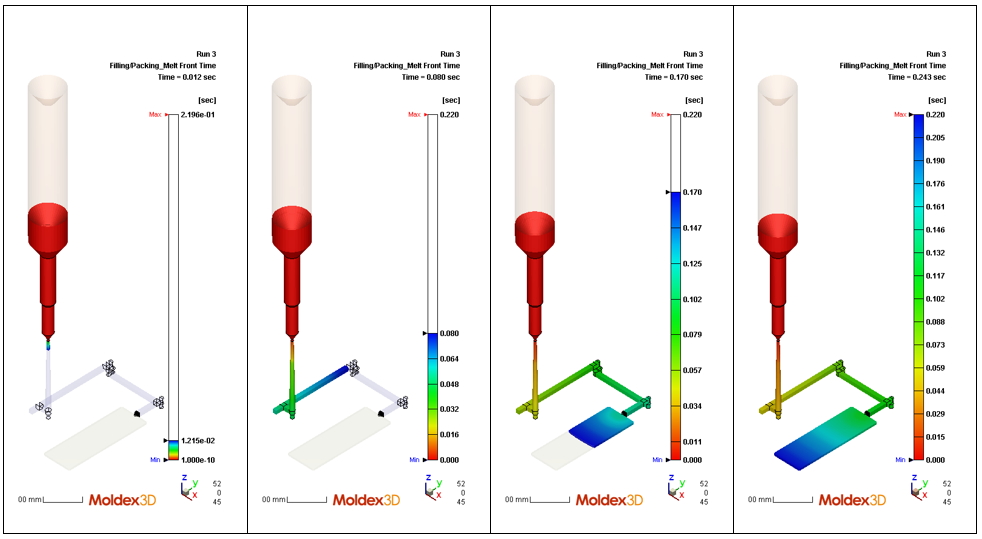

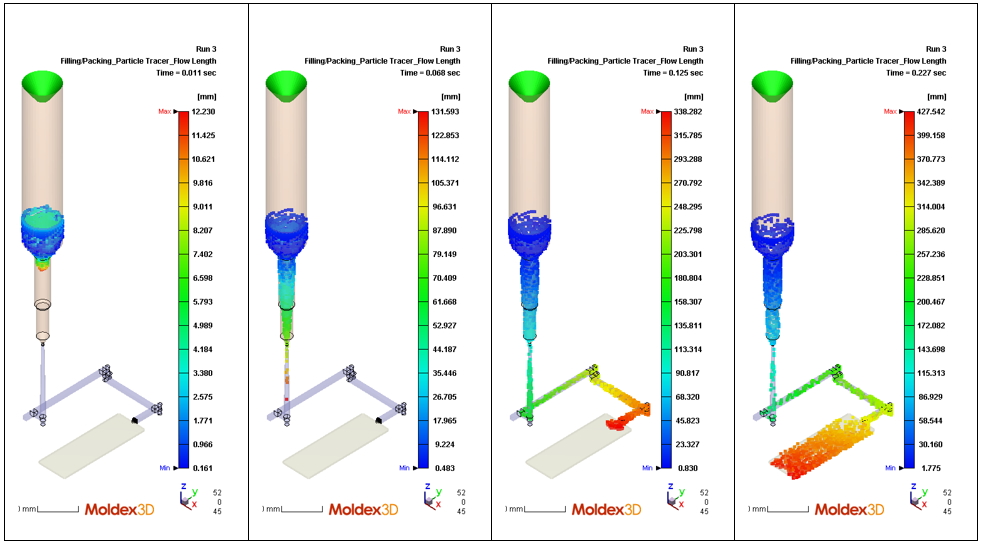

The Operation Processes

Melt Front Time

Particle Tracking

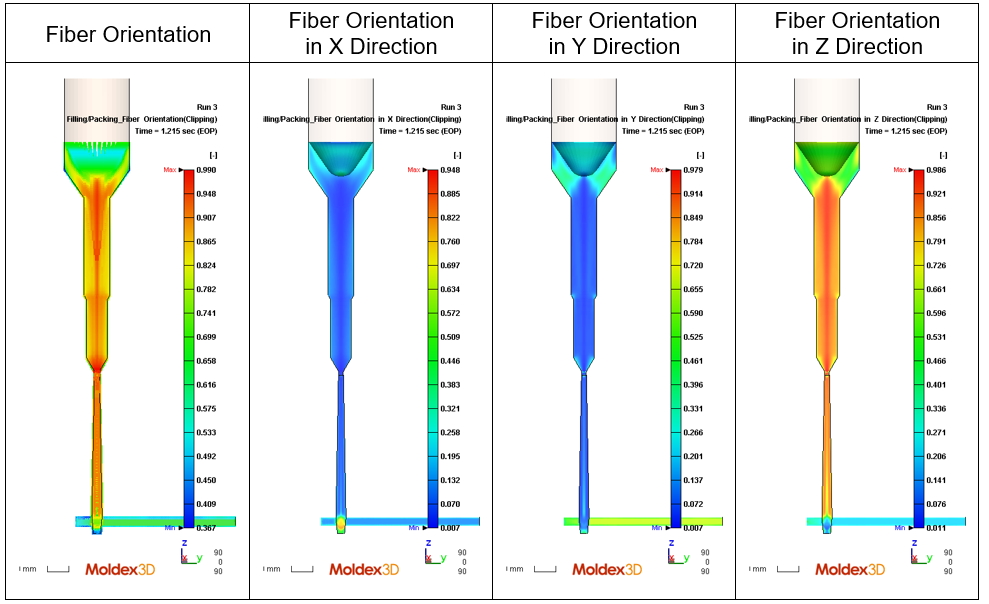

Fiber Orientation (Clipping)